BlueScope Steel Coating Mass Gauge- Springhill Works

Introduction

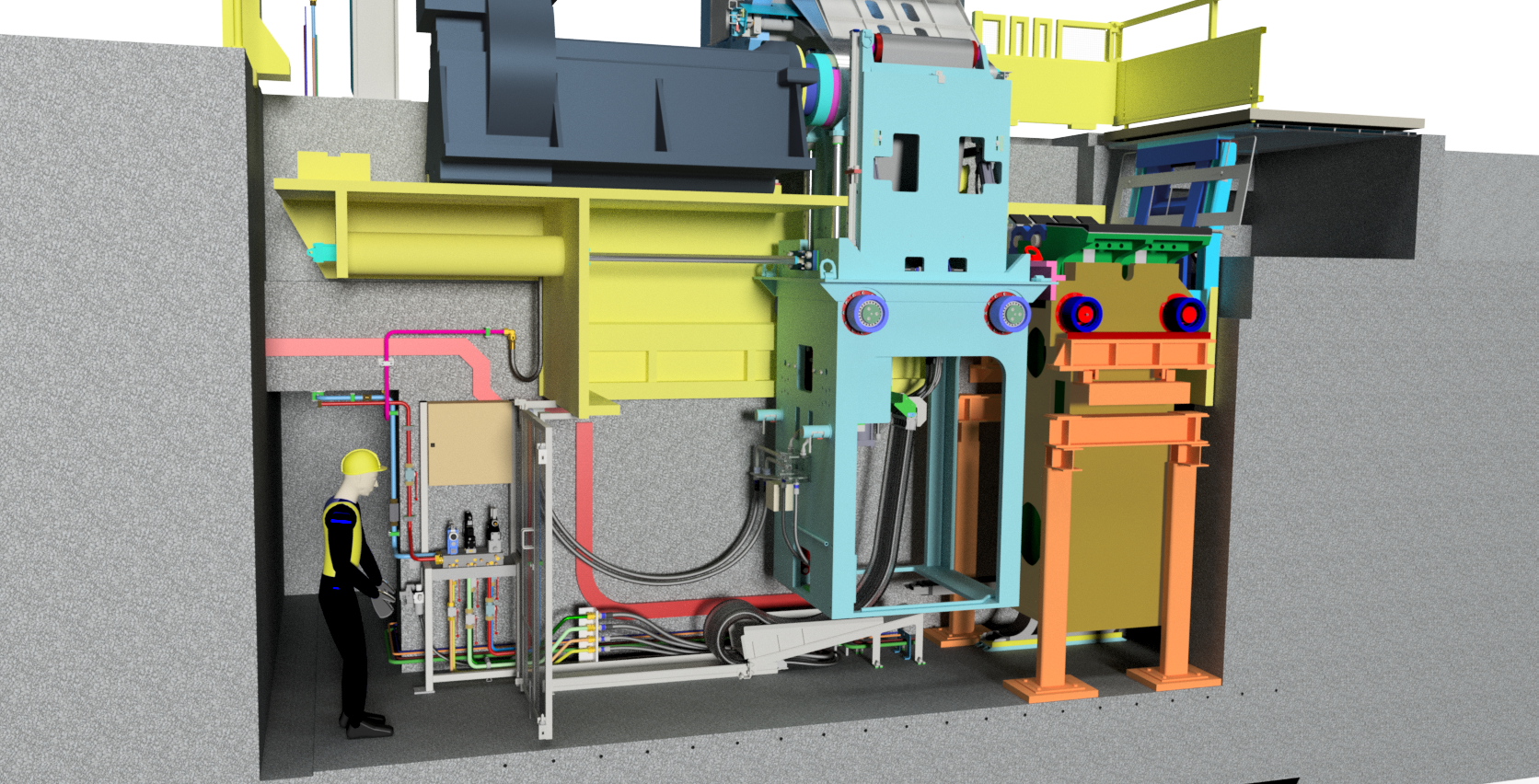

Our team successfully completed a series of critical upgrades to the Coating Mass Gauges (CMG) at BlueScope Steel's Springhill Works, involving the MCL1, MCL2, and MCL3 lines. This project aimed to modernize the existing systems with advanced X-ray technology, enhancing operational security and ensuring the economic viability of the metal coating lines.

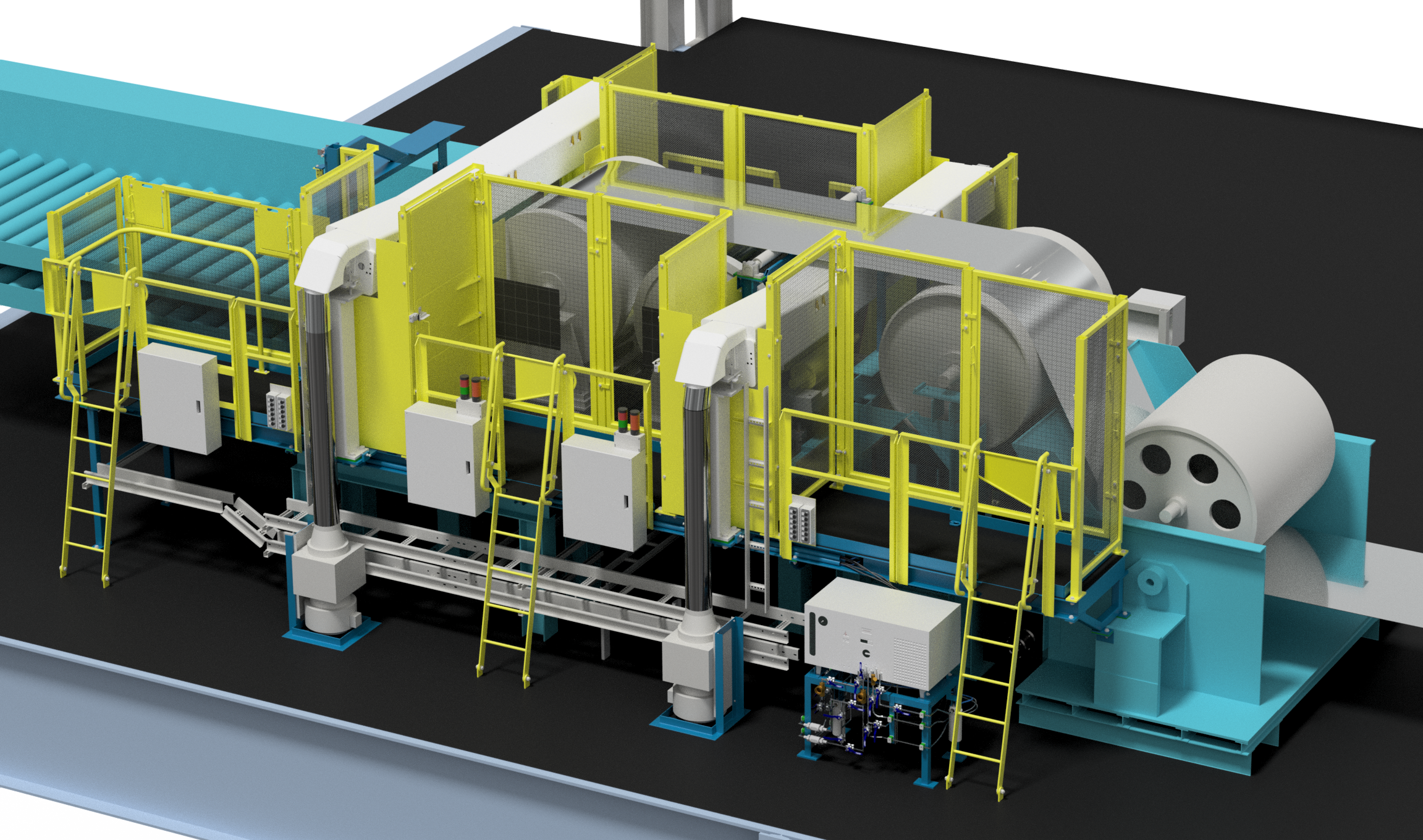

3D Model of CMG 3 Roll arrangement, supporting structure, gauge equipment, guarding and safe access platforms.

Project Budget

MCL1: $1,400,000

MCL2: $1,200,000

MCL3: $1,900,000

Project Purpose

MCL1 & MCL3: Replacement of outdated 1970s isotope-type CMGs. The new equipment is strategically relocated closer to the hot metal pot to improve coating control efficiency.

MCL2: Upgrade of the 1980s X-ray type CMGs, with the new system installed in the original location due to space and operational constraints.

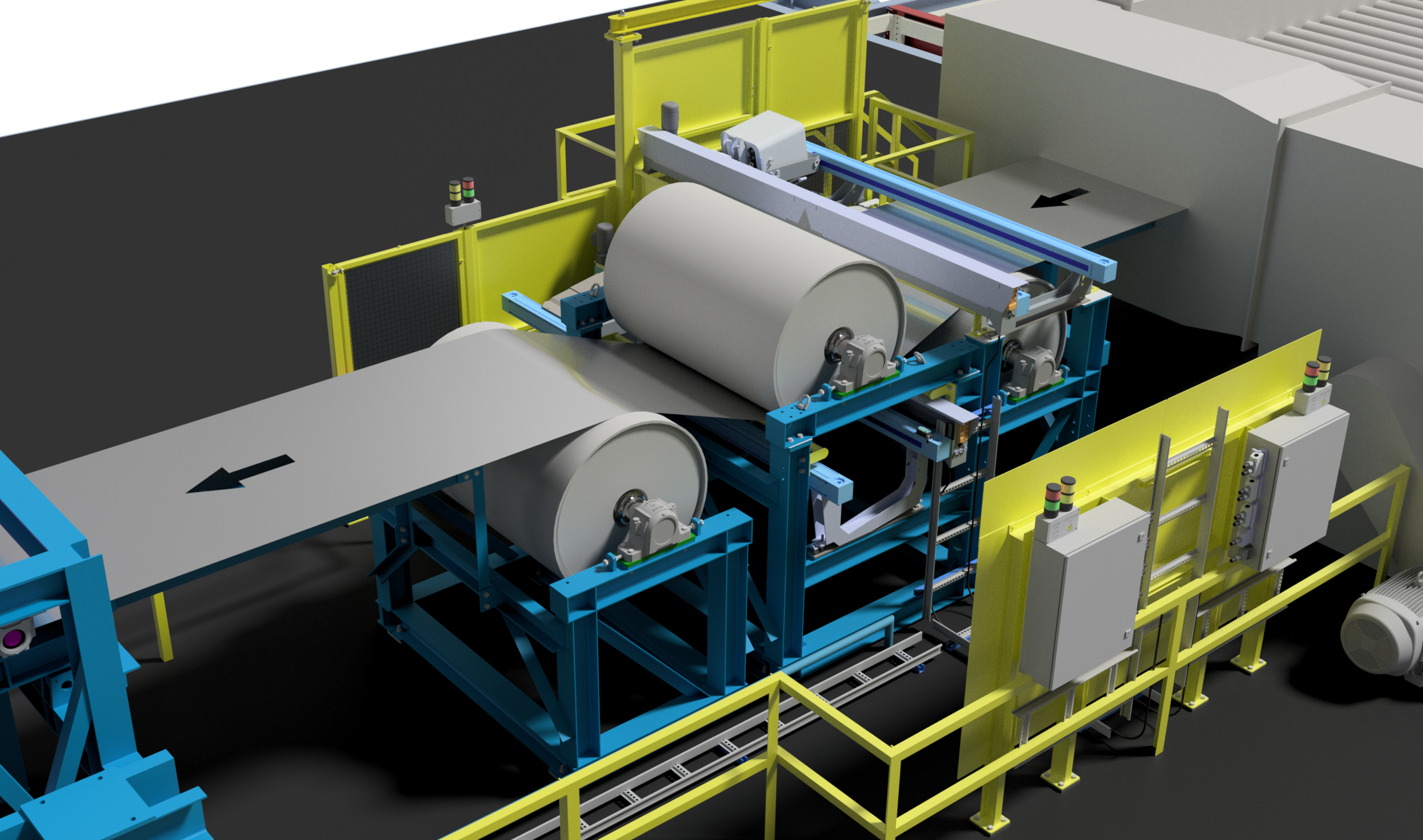

3D Model of CMG Roll arrangement, supporting structure, gauge equipment, guarding and safe access platforms.

Engineering Feats

The design phase for MCL1 and MCL3 was meticulously planned to allow for a staggered installation, minimizing line downtime.

A total of 165 unique detailed drawings were created to guide the fabrication, installation, and future maintenance of the new systems.

Outcome

This project not only modernizes the technology at BlueScope Steel Springhill Works but also ensures compliance with current standards, reduces maintenance costs, and improves the precision of the coating process, thereby securing the facility's competitive edge in the steel industry.

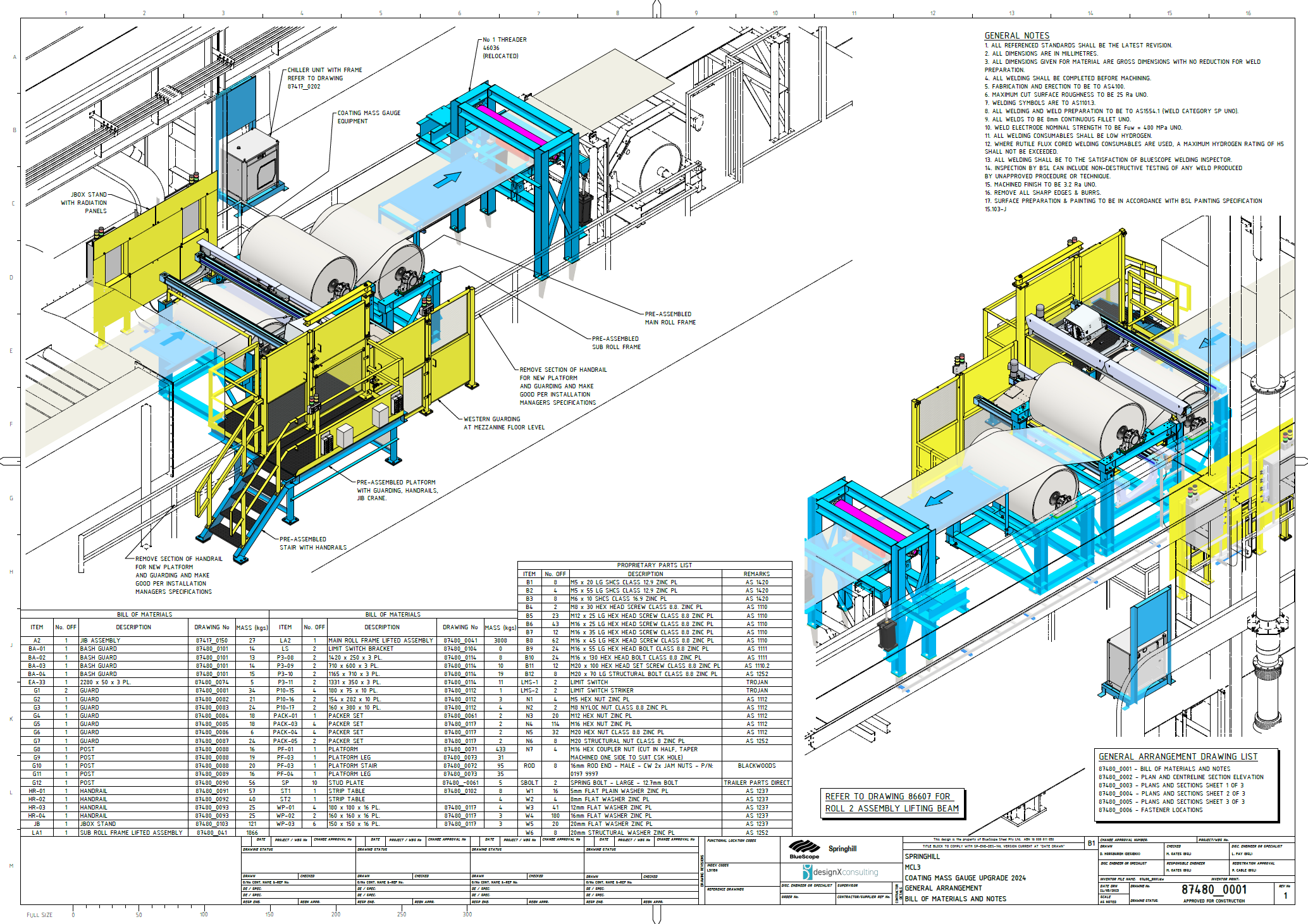

Platform and Guarding Arrangement Drawing

General Arrangement Drawing