Bluescope Steel MCL Belt Wrapper Upgrade - Springhill Works

Project Overview

Our company undertook a significant upgrade project for the Metal Coating Line (MCL) Belt Wrapper at BlueScope Steel's Springhill Works. This project focused on replacing an antiquated 1960s design with a modern system capable of handling a broader range of product thicknesses, enhancing operational flexibility and efficiency.

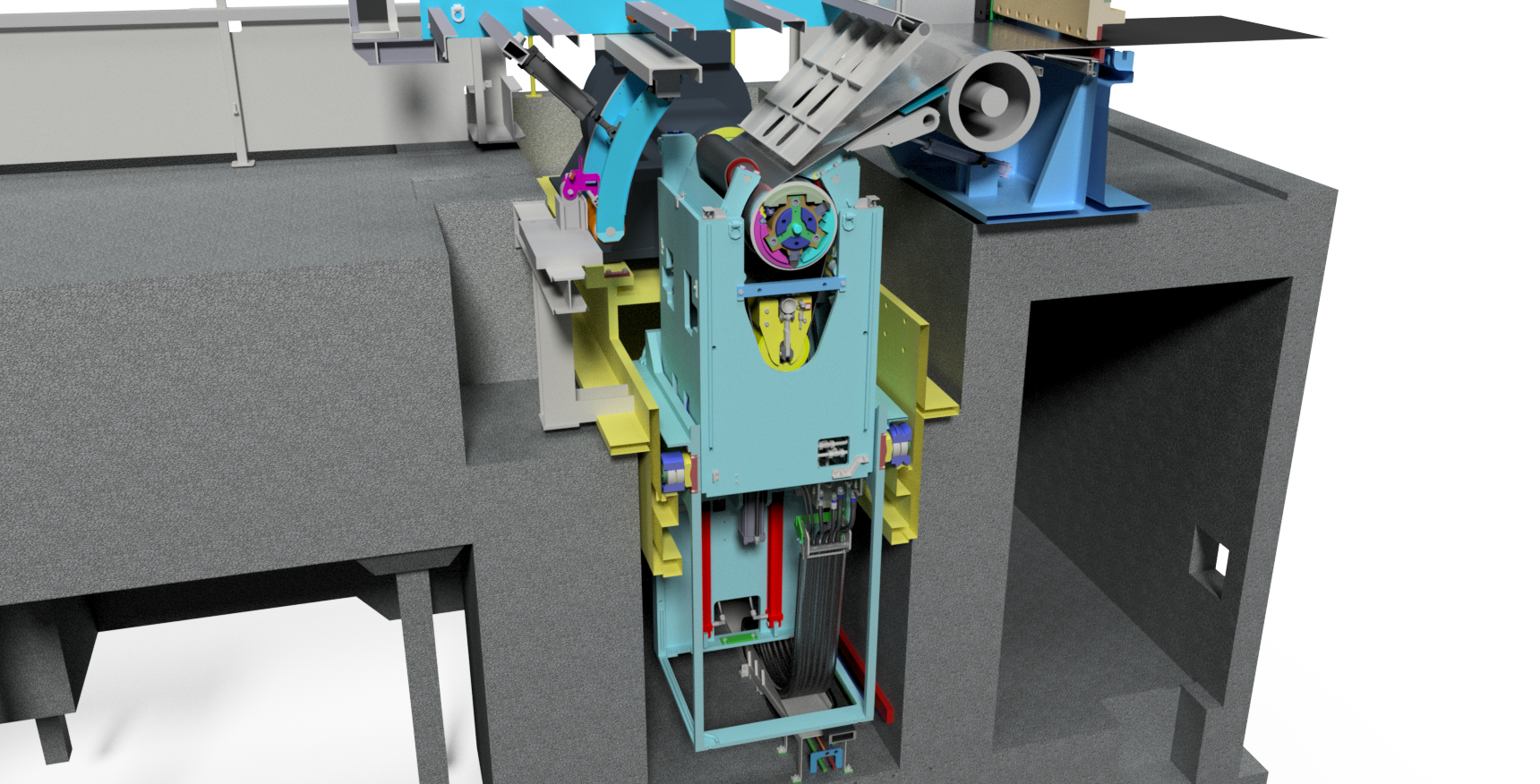

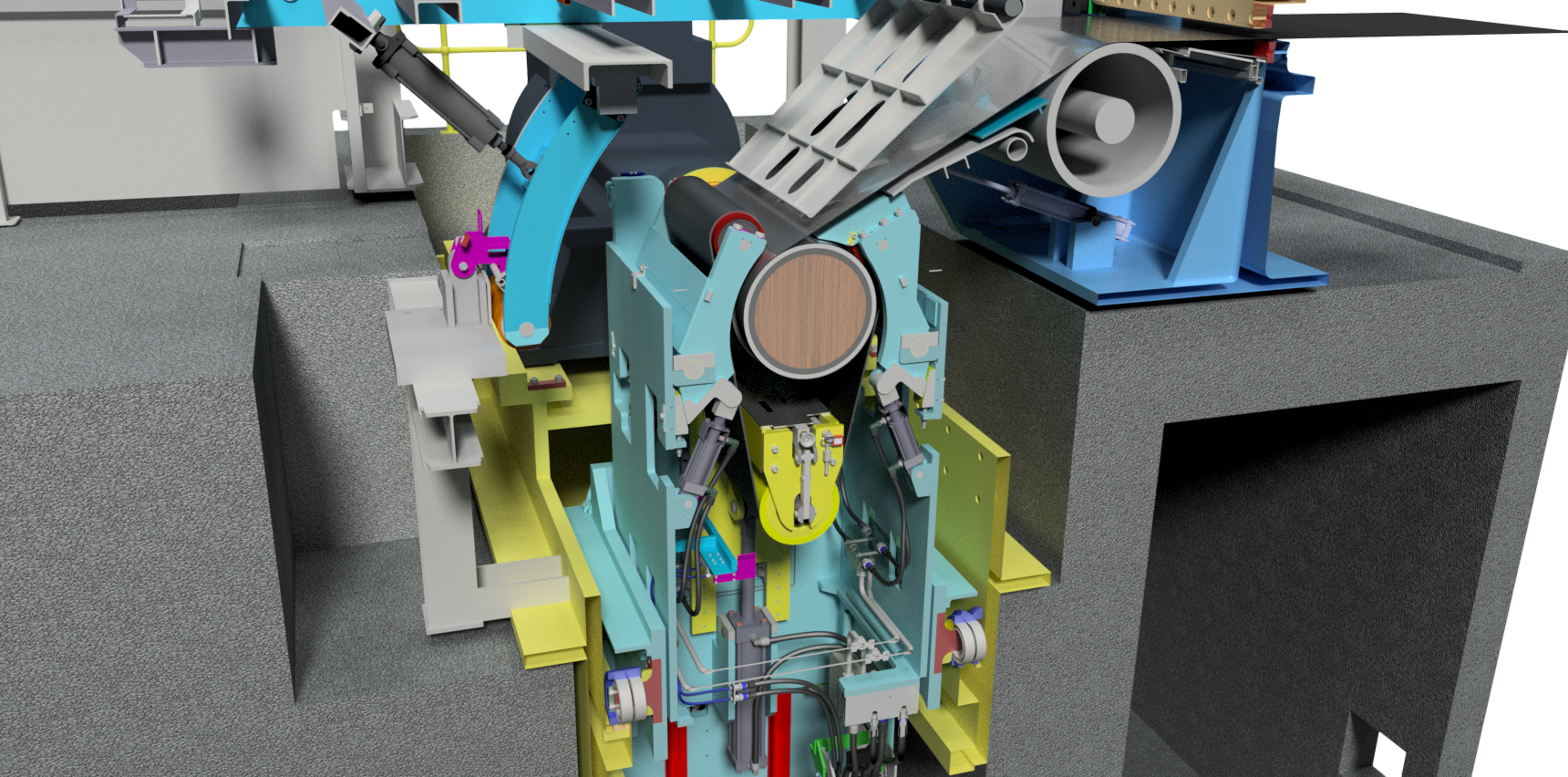

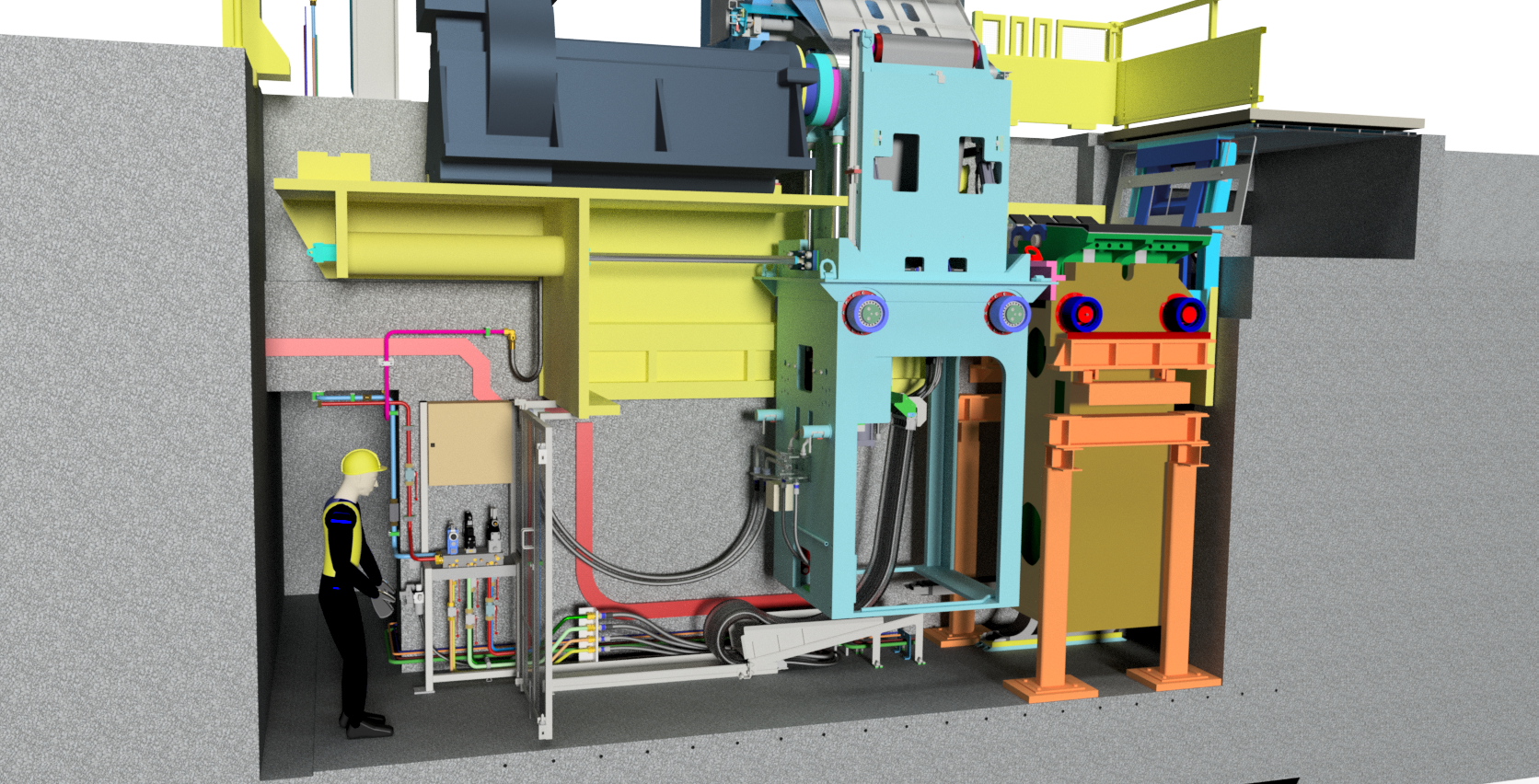

Sectional 3D model view of Belt Wrapper Arrangement

Project Budget

Total Budget: $980,000

Project Purpose

The primary goal was to replace the outdated belt wrapper system, which had limitations in handling thicker steel strips, requiring the use of a gripper slot in the recoiler mandrel for products over 1.9mm thick.

The new system was designed to accommodate the complete product thickness range from 0.5mm to 3.5mm without the need for the gripper slot, thereby simplifying the process and reducing setup times.

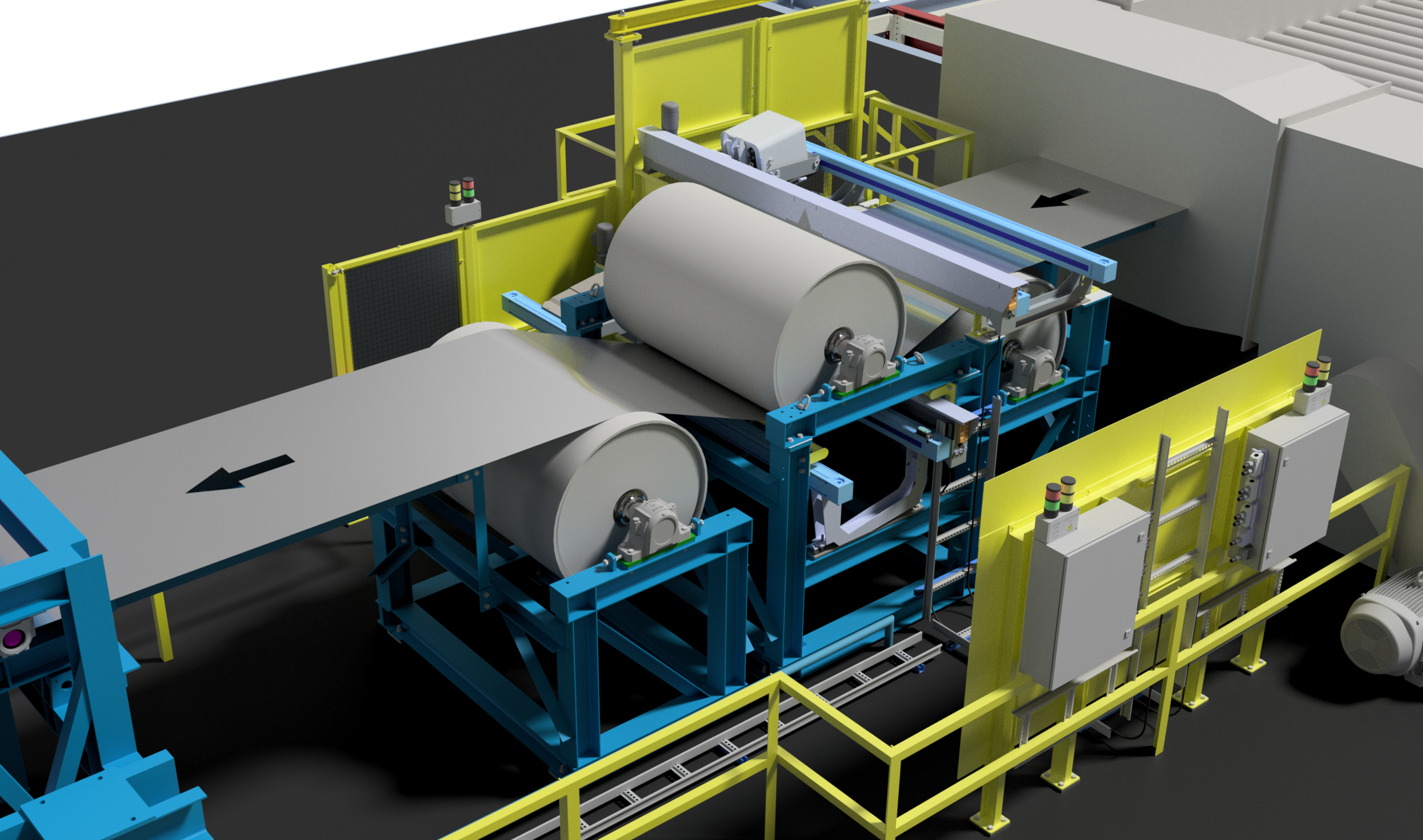

Sectional 3D model view of Belt Wrapper Arrangement

Project Highlights

Increased Capability: The upgraded belt wrapper now efficiently processes the entire thickness range, improving production versatility and throughput.

Economic Efficiency: The project boasted a payback period of less than 2 years, showcasing its economic viability and the immediate benefits to production efficiency.

Implementation

Installation: The new belt wrapper was successfully installed and commissioned in November 2019, marking a swift transition to the upgraded technology with minimal disruption to ongoing operations.

Engineering and Design

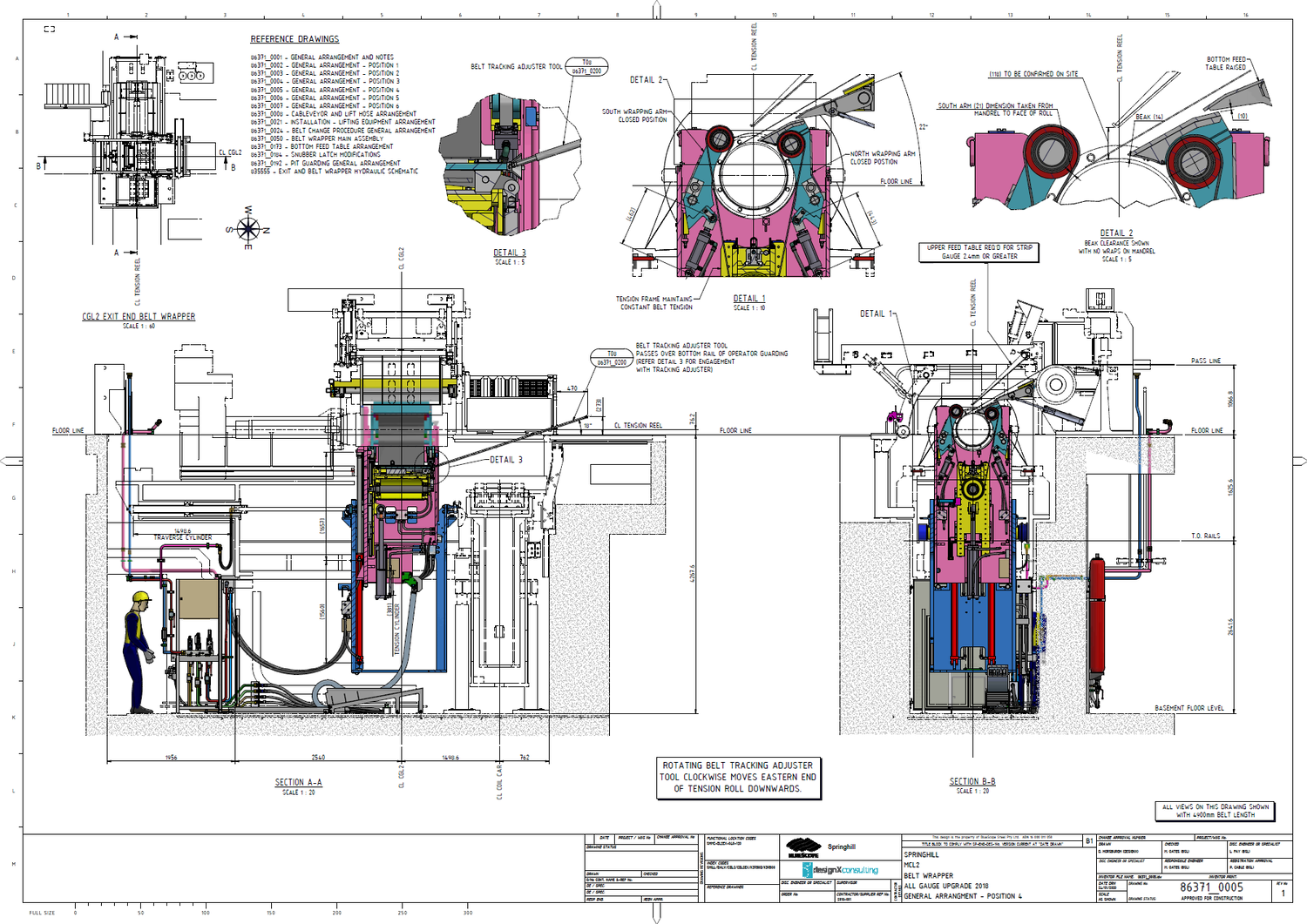

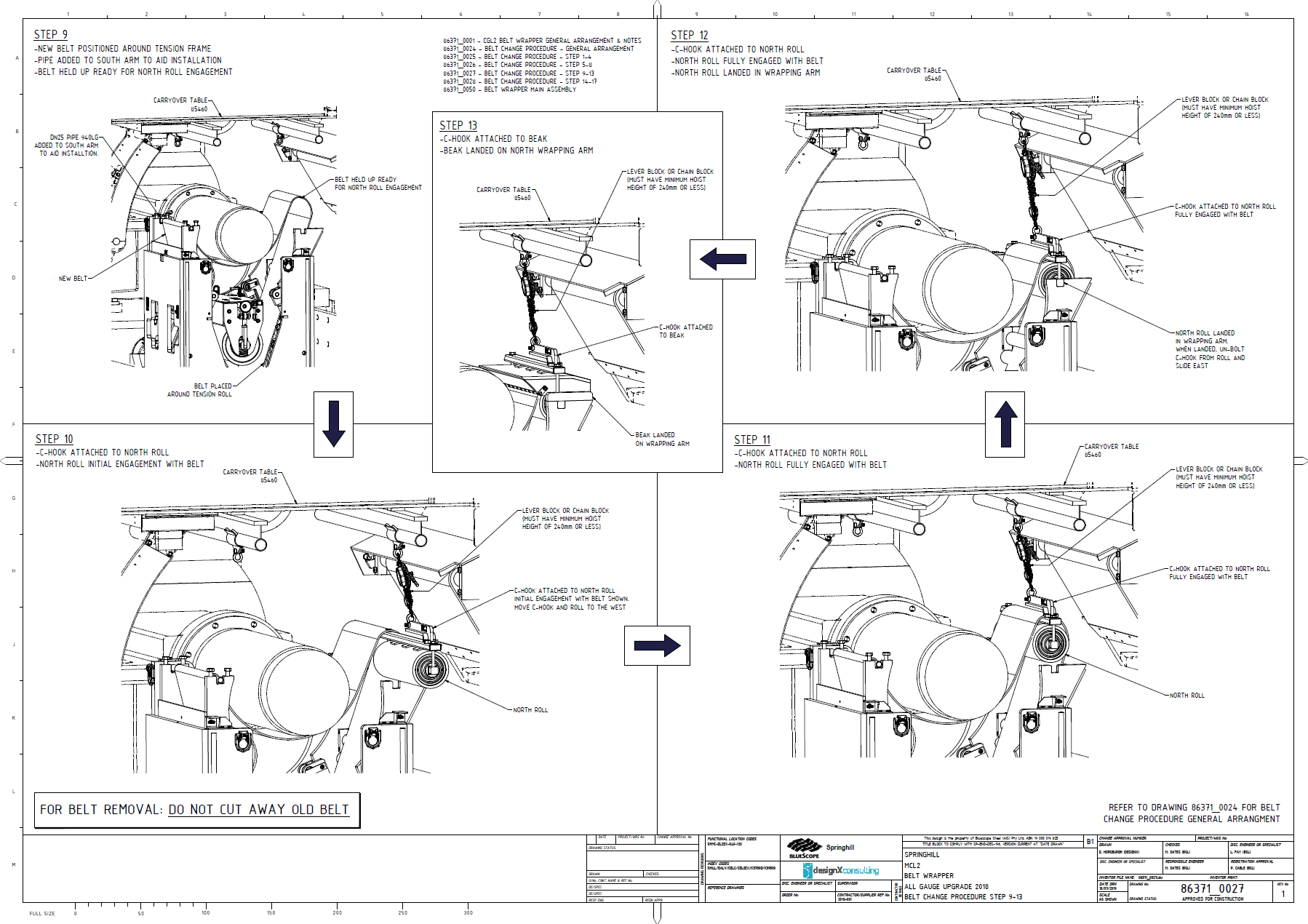

Drawings: A comprehensive set of 165 unique detailed drawings were produced, ensuring precision in the fabrication, installation, and future maintenance of the new belt wrapper system.

Outcome

This upgrade has significantly enhanced the operational capabilities at BlueScope Steel Springhill Works, allowing for greater flexibility in product handling, reducing operational constraints, and contributing to the plant's overall productivity and competitiveness in the steel manufacturing sector.